Introduction

This project began as a 2nd year project to develop a Powered Wheelchair Simulator for children with cerebral palsy, helping them gain proficiency before using a real one. This project encompassed various components: electrical, computational and mechanical which helped me discover a passion that lies in the mechanical aspects of engineering.

The mechanical aspect focused on building the rig and ensuring its structural safety. I spent significant time in The Advanced Hackspace, where I applied various workshop techniques such as drilling, lathing, welding, and waterjet cutting, while incorporating CAM techniques throughout the process.

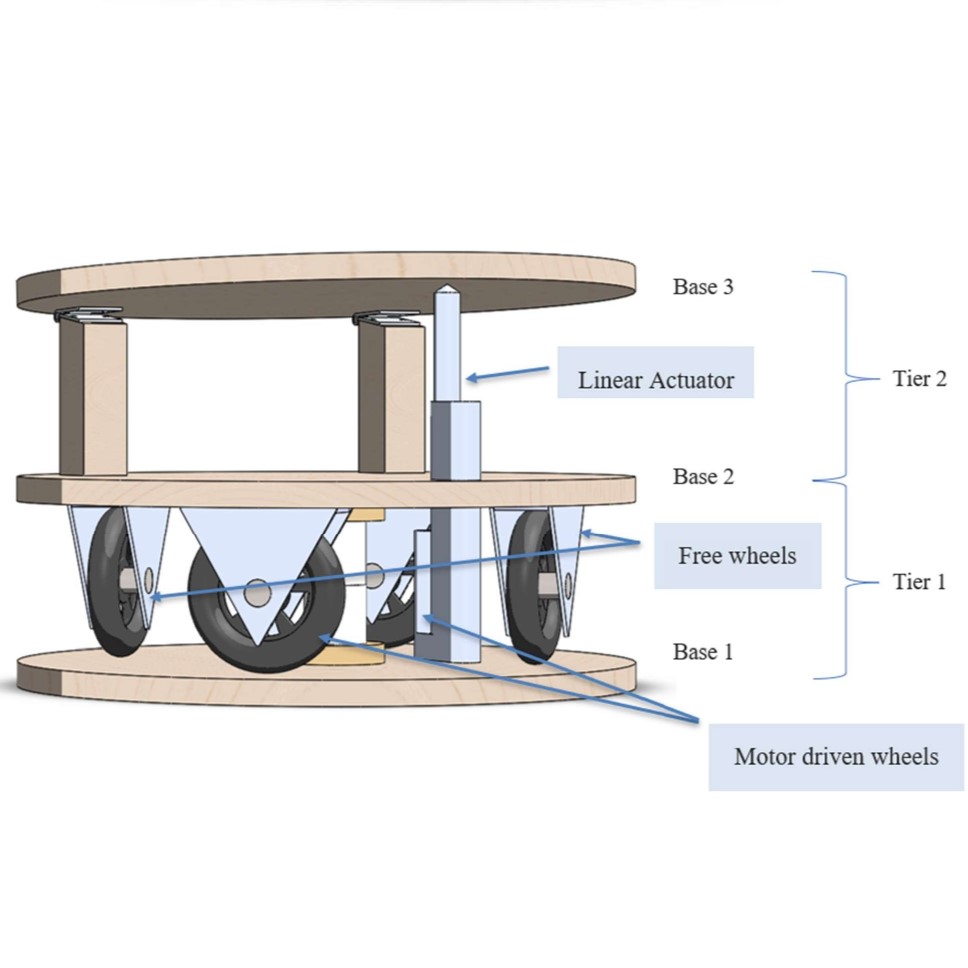

The electrical aspect involved using a linear actuator to move the plate up and down to simulate acceleration, and motors to rotate the simulator clockwise and anticlockwise around its centre.

The computational aspect involved the creation of a game that worked in sync with the rig and electronics, accurately providing visual feedback to mirror the observed movements.

Iteration 1

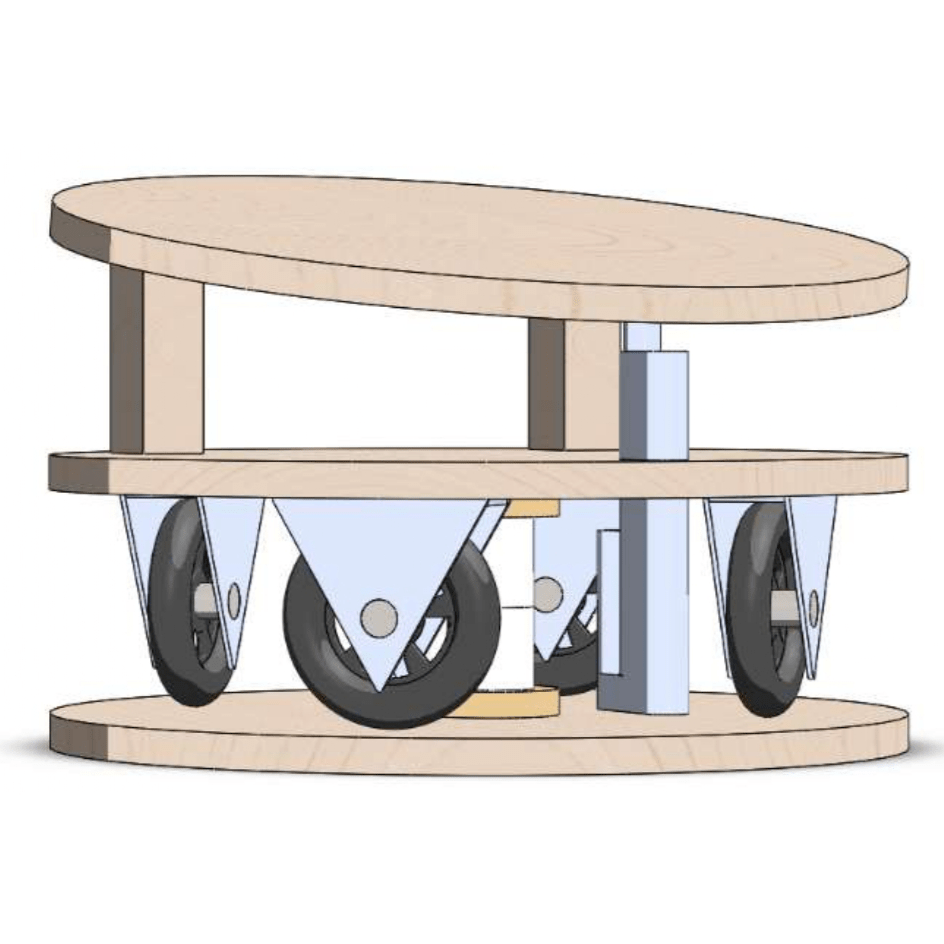

It was made of three sections:

- Bottom layer – the main plate which needed to carry the weight of the whole wheelchair and where the wheels would run to simulate rotation.

- Middle layer – to house the electronics used, to act as an attachment point for the monitor and to hold up the linear actuator

- Top layer – the connection point for the tip of the actuator and to secure the specialised chair in place for users.

Iteration 2

Worked closely with The Pace Centre UK

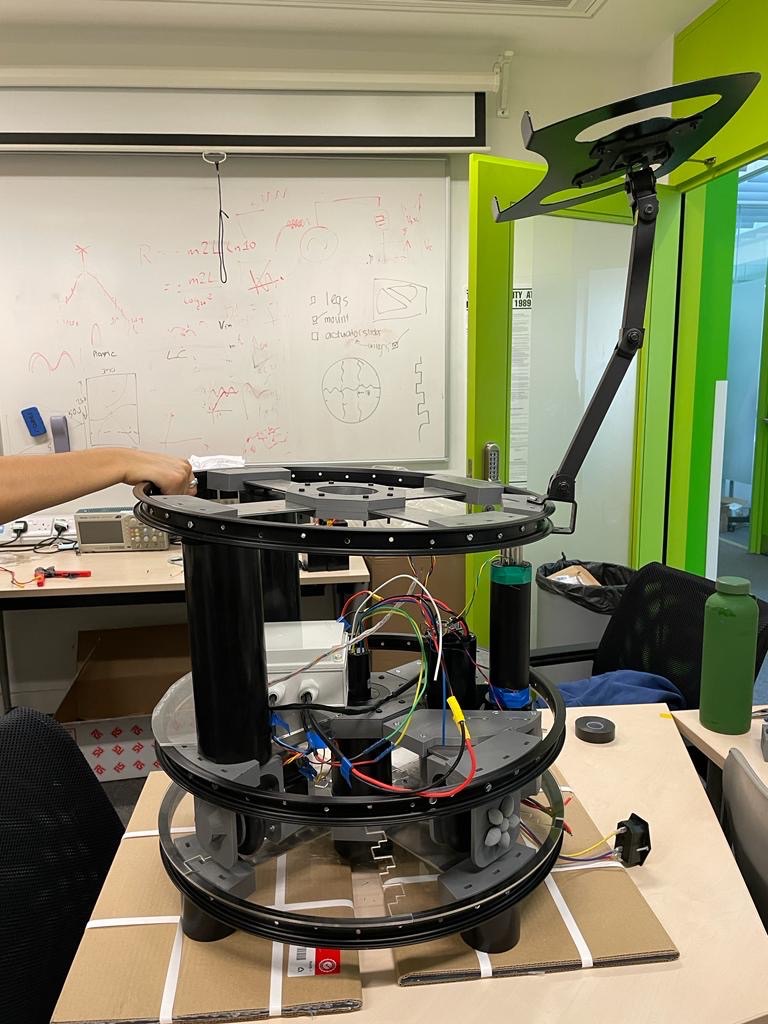

The main goal of the summer UROP was to work towards a commercialised prototype, focusing on redesigning the mechanical aspects, making the game more realistic, and improving the safety and efficiency of the electronics.

The improvements:

- Replacement of wood to metal to prevent risk of fire hazards

- DC supply was switched to mains supply

- Upgrading the motors and actuator to handle higher loads

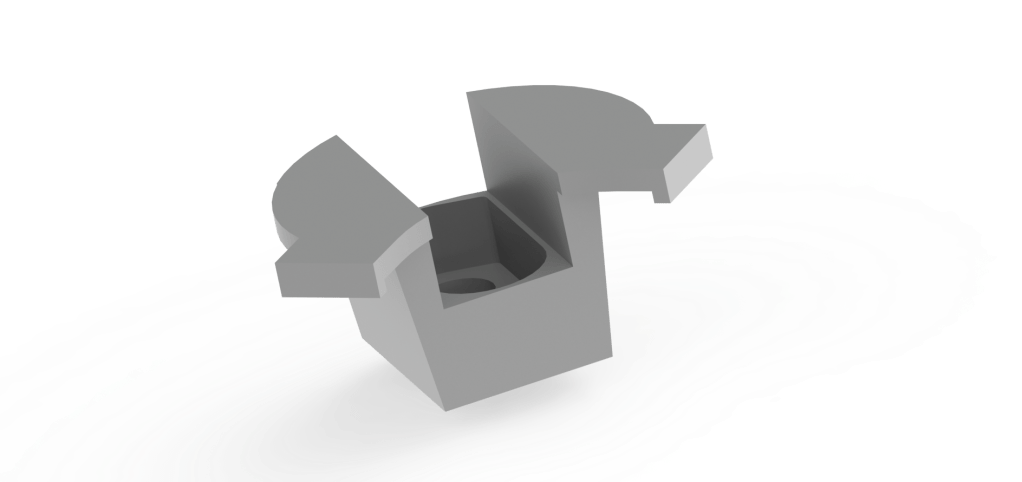

- Stronger materials were used, and most parts were 3D-printed with PLA for precision and efficiency

This allowed me to enhance my SolidWorks skills, particularly in designing an improved actuator bracket, and gain further experience with various workshop techniques.

Iteration 3

The focus was to improve the strength, durability, and ease of maintenance for the device. Most components were reprinted using carbon-fibre PLA for added strength, while key parts were remade into aluminium to enhance structural integrity. This required redesigning the CAD models to accommodate the new materials and ensuring compatibility for both assembly and disassembly to simplify maintenance. These upgrades helped refine the prototype for potential real-world applications, further advancing my SolidWorks skills and my understanding of mechanical systems.